9" x 12" Laser Photoplot Film

Laser Photoplot Film

Film Size: 9" x 12" - 228mm x 305mm

Image size: 8.6" x 11.6" - 218mm x 295mm

This film has a maximum image size of 8.6" x 11.6" - 218mm x 295mm

All of our standard resolution laser photoplot films (also known as Photo Tools, Laser Plots, Mylars, and Film Pos's depending on your industry) are imaged and processed using the latest high-tech technology, which is a fully automated process allowing us to queue and image films whatever part of the day - or night. This automation helps to improve quality by reducing handling - and of course means that we have a high capacity in production..

Our laser photo plotted films are ideal for use as PCB phototools, Photo Etch film tools, all sorts of photo resist exposure masks, and are also perfect for graphics applications.

DISCOUNTED PRICES

Where discounted prices are shown for multiple quantities, this is based on a DUPLICATE film from the same design, processd and imaged as part of the same order.

BASE MATERIAL

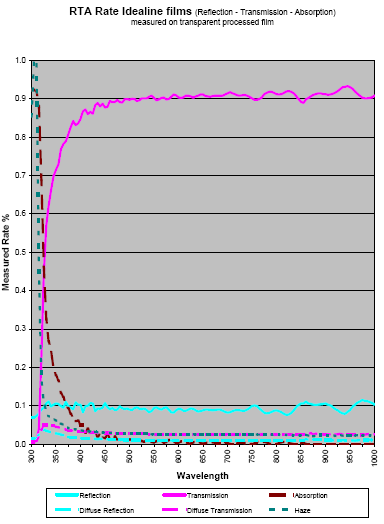

All of our laser photoplot films are imaged onto Agfa Idealine film 0.18mm thick polyester film which has a photographic emulsion coated onto one side. These are specially manufactured for consistent high quality results. They are both imaged, and inspected, in controlled environments which is crucial to their dimensional stability. For the most accurate films possible, please use this films in an environment of 21 deg C and 50% humidity.

RESOLUTIONS

We can write masks at 2 different resolutions. The higher the resolution, the better the qualtity. Please see the tab SPECIFICATIONS to see the impact that class resolution has on dimensional accuracy and feature tolerances.

4k dpi : LOW Resolution. These films are suitable for general low resolution printing applications, such as screen print and tab printing. They can also be used for photoetching / photofabrication films and low resolution PCB type applications. Although this resolution may resolve smaller features, we recommend keeping feature sizes above 0.2mm as corner rounding is considerable. Edge sharpness and definition is acceptable for non critical design types, although designs with arcs/circles and lines running off 90 degree grid may show pixilation. NO features such as lines / circles / spots / squares below 0.1mm unless on a 'best effort' basis previously agreed with our technicians.

10k dpi : LOW Resolution. This resolution will usually resolve down to 0.1 mm lines with improved line edge qualities with only a slight pixilation along edges. Corner rounding is still noticeable under magnification. NO features such as lines / circles / spots / squares below 0.08mm unless on a 'best effort' basis previously agreed with our technicians.

DATA FORMATS

We can accept various formats of data. Whilst Gerber remains the most common for the PCB and electronics Industries, we also have the ability to image from postscript, graphics files and Adobe Illustrator for our customers based more in the Graphics Industries. And, of course, common CAD formats such as DXF, GDSii can also be manipulated. These data formats listed above are only a small section of what is available - please contact us for further information and clarification. We are also able to provide a full drafting service whereby we can create your designs from drawings and descriptions.

PRODUCTION SCHEDULE

Standard leadtimes from receipt of data to shipping are 24 hrs, but where orders are very urgent and prompt delivery is critical to a projects success - you can count on us to deliver by offering a sameday service - from receipt of order to shipping of films in the same production day ! If this service is required, please let us know as soon as possible during the day in order that we can get production time scheduled for your order.

INSPECTION

Standard : We inspect the piece by eye for flaws, design inaccuracies and contaminations.

Enhanced : In addition to the standard inspection process described above, we will then document them via a Certificate of Conformance which we supply with the mask. Tolerances are per our standard tolerances. We will choose one measurement for length, and one for feature size.

Full Certificate : By selecting this option during the ordering process, we will inspect upto 10 customer defined measurements, with customer supplied tolerances. You will need to send us a document, or a separate layer of the design, showing us where you want us to take the measurements from. There can be upto 10 positions defined by the customer. These dimensions are then programmed on the co-ordinate measuring system and the mask is compared to this unique program. A certificate of conformity is given if the mask passes the inspection process.

Please see the TECHNICAL sections, DOWNLOAD sections and FAQ for further information. If you still require clarification, pleas either email or click for LIVE SUPPORT.

FEATURE TOLERANCES

There are two different values that we specify for tolerances. The first is a ‘feature tolerance’, which equates to one specific feature (also known as CD or Critical Dimension). So, if part of your mask design has a 0.1mm dot and this is a critical feature, you can use the table below to work out possible deviations to the dot size, depending upon which resolution you choose. As a rule, the higher the resolution, then the more accurate the individual feature size will be. if you need better tolerances than are quoted below, please see our HIGH RESOLUTION photomask films.

|

Resolution

|

Material |

Tolerance |

|

4k dpi |

polyester film |

+/- 25um |

|

10k dpi |

polyester film |

+/- 15um |

All figures above in Microns....

DIMENSIONAL TOLERANCES

The second tolerance that customers ask us about is that of overall dimensional tolerances. These refer to the tolerances over a distance greater then 5mm – in layman’s terms, people ask us ‘how accurate will the mask be’ and these guidelines should go somewhere towards providing the tolerances in overall dimensions ,depending upon the resolution chosen. Again, it goes without saying that the higher the resolution, then the more accurate the final mask. if you need better tolerances than are quoted below, please see our HIGH RESOLUTION photomask films.

Our photo-mask films are produced in conditions of 21deg C / 50% humidity, and if dimensional accuracy is a concern when using the polyester mask, then you must replicate these conditions in your own clean rooms and acclimatise the mask in these conditions for upto 8 hours before you intend to use it – only then can it be considered to be dimensionally accurate and stable. We strongly recommend using glass based substrates where dimensional stability is a concern.

NOTE:

When using films in your own production environemnt, be aware that ....

1 Deg C temperature change = 18 ppm (1.8um per metre length)

1% Humidity change = 9ppm (0.9um per metre)

|

Resolution

|

Microns |

|

|

where L is measuring length in MM and the resulting |

|

Low Resolutions |

= 20.0um + (Lmm * 0.010) um |

All figures above in Microns....

Example, a 100mm line would have a tolerance of (20.0 + 1) = +/- 20.1um

SPECIFICATION

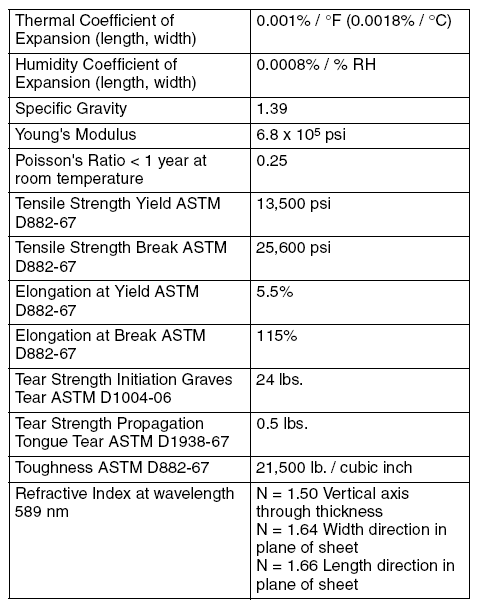

Polyester Film is a typical substrate used in the photographic process, and forms the most common substrate in applications that involve general multiple exposures (such as PCBs, etching, printing etc.). Polyester is excellent due to its low-cost nature, but must be handled carefully and used in controlled environments if dimensional accuracy is required.

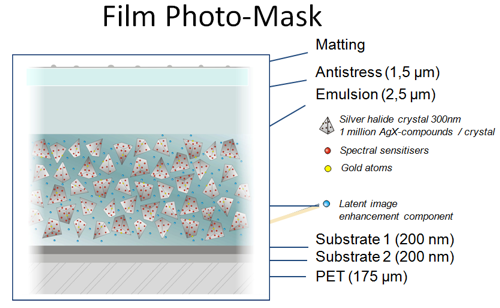

Films used for photo-masks have the following component layers: a plastic base, a photosensitive emulsion layer (silver halide) and a backing layer.

This plastic base is polyester material, and has a thickness of 0.18 mm. The emulsion layer is composed of gelatine and silver halide and other chemicals, which adds another 0.005mm in total.

When we expose the film in the imager, the light energy from the laser interacts with the silver halide crystals suspended in the coated gelatine layers. Development, a chemical process, converts exposed silver halide grains into metallic silver. The next step in the chemical process is fixation. The fixer stops development and removes the unexposed silver halide grains in non-image areas. Finally, the film is washed/dried/cleaned and inspected.

The final result is a ‘black’ image coated on one side of the polyester base. The density of the film is very high, typically Dlog of 4.5 – 5, giving it an excellent opacity to all common light sources.

Two concerns with emulsion film over glass are stability and robustness. Both the polyester and the gelatine absorb moisture and heat from their surroundings, and as such they undergo dimensional changes – quite considerably for some large area films. The other problem with the Gelatine/Emulsion is that it is relatively soft and must be handled carefully to avoid damage and scratches.

Our photo-mask films are produced in conditions of 21deg C / 50% humidity, and if dimensional accuracy is a concern when using the polyester mask, then you must replicate these conditions in your own clean rooms and acclimatise the mask in these conditions for upto 8 hours before you intend to use it – only then can it be considered to be dimensionally accurate and stable. We strongly recommend using glass based substrates where dimensional stability is a concern.

FAQ's

Q: What does the term NEGATIVE and POSITIVE mean ?

A: Polarity is the tone of the photomask. When you draw your design, polarity determines whether the features on the film are CLEAR or BLACK on the final film. So, a NEGATIVE film would have the items you have drawn in CAD as CLEAR on the film. Obviously this is the opposite for POSITIVE, where the items you drawin CAD are BLACK on the film.

Q: I've designed my mask with the wrong polarity - what do i do ?

A: We can use the original design file and simply reverse the tone of the mask. This is much easier than supplying new data.

Q: What is Right Reading, Wrong Reading and Mirrored.

A: Its important to specify the View Side of the film. Right Reading Emulsion Side Down is the most common way to describe a film that will be used for contact lithography... so when you hold the film in your hands with the emulsion side facing down closest to the material, the image on the mask will be correct reading (text) . Alternatively, you can also specify the film as Right Reading Emulsion Side Up. We can very easily change the "view side" before we image the film by "mirroring" the data.