Photoplotted Film Calibration

Level 2 Monthly Calibration

Photoplot file provided

Certificate returned

MONTHLY CALIBRATION SERVICE

Our service provides a monthly measurement service to ensure that your photoplotting or imaging equipment is kept fully calibrated - giving you the chance to be pro-active to oncoming problems rather than reactive when things go wrong. The service is simple - we give you a photoplot gerber file, you run one copy each month and send us the film. We allow the film to acclimatise before measuring. Once measured, a full C-of-C will be issued .

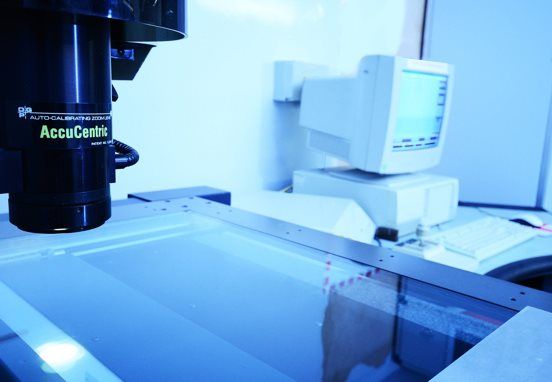

All measurements are taken in controlled environmental conditions of 21deg C (+/- 1 Deg) and 50% humidity (+/- 5%), using an OGP ZIP 300 at 400 x magnifications.

NIST Level 2 Certificate

We issue this service as a Level 2 NIST standard: "A calibration, which may be carried out in-house, performed to a documented method by competent staff, using appropriate reference standards/equipment. The reference standards/equipment will need to be calibrated by a laboratory that can demonstrate competence, measurement capability and traceability, e.g. a UKAS accredited calibration laboratory."

The environmental conditions are recorded on the certificate, to enable sizes and dimensions to be extrapolated back to know conditions.

CAD FORMAT

The file supplied will be a gerber file. DPF or ODB++ are also available on request. It's important to use the file supplied by us with no modifications - it includes a pre-defined set of targets and fiducials that our measuring systems can find and scope automatically.

MEASUREMENTS

Dimensional: A series of dimensional measurements are taken on the film, related back to a given origin point. Dimensions are taken in X, Y and diagonal to allow you to confirm the overall scale and squareness of your photoplotter. The overall dimension of the targets are recorded on our internal inspection records, and copied across to the spreadsheet certificate automatically.

Option 1 - linewidths: In addition to the standard inspection process described above, we will then measure line widths by finding the CD (critical dimension) of the calibration target that we place on the file, measure that, record it, and also take a digital photo that is saved with the inspection log. We use Nikon MM40 at 900x magnification.

Option 2 - Density : By selecting this option during the ordering process, we will inspect density in 2 opposite corners of the film, and this again is recorded and marked on the insoection certificate.

Please see the TECHNICAL sections, DOWNLOAD sections and FAQ for further information. If you still require clarification, pleas either email or click for LIVE SUPPORT.

SPECIFICATION

Specifications here

FAQ's

Q: How accurate are the features, what tolerances do you work to ?

A: This is dependant upon the resolution that we image the mask at. The QUICK REFERENCE brochure in the DOWNLOADS section will give you a chart, specifying both feature and dimensional tolerances.