Chrome Specifications

The chrome is coated onto the plates in very thin layers, the thickness may vary depending upon the OD (Optical Density) required - but generally ranges in the 0.1um to 0.15um thick. The chrome surface can be coated with an oxide layer to change its reflective properties.

OXIDE COATINGS AND REFLEXCTIVITY

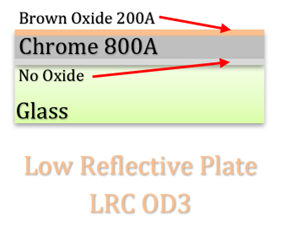

LRC – Our standard product is a LRC (Low Reflective Chrome) which reflects lowest in the UV wavelengths. and therefore, is most suitable for applications using Mask Aligners and other UV exposure equipment. This oxide makes the top surface appear “brown/gold” to our eyes and is the most common coating type that we offer. The bottom face of the chrome – against the glass – remains high reflective.

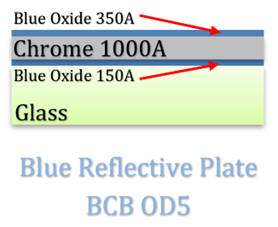

BCB – We have a small selection of BCB chrome (Blue-Chrome-Blue) in stock. This is low reflective when using the plate in the visible spectrum, so is the best solution for standard optical components . With this material, the oxide applied to both surface of the chrome (face to air, and face to glass) so it will appear identical when looked from the front (chrome side) or the back (glass side). Note that Blue oxide coating can be “tuned” to different wavelengths, such as 650nm, 800nm, 850nm etc (MOQ applies).

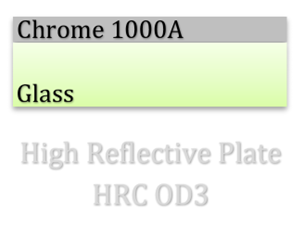

HRC - We also have a small range of High Reflective chrome. This chrome still NO oxide coating over the surface, so the top face is almost as reflective as the bottom face.

TRANSMISSION

Although the chrome coating is generally "opaque" and blocks light, some wavelengths will always transmit through the chrome coating. The amount of transmission is very low, but it will vary according to the thickness of the chrome and the wavelength of the transmission light.

The table below show the relationship between Optical Density and Transmission of Light through different chrome thickness in the visible wavelengths.

Our standard products for most smaller plates that we hold in stock are OD3... that’s to say that they are guaranteed to be higher than optical density 3 when used in the wavelength range of 350-450nm (UV exposures).