CHROME SPECIFICATIONS

- Coatings

- The chrome is coated onto the plates in very thin layers, which thickness may vary depending upon the OD (Optical Density) required - but generally ranges in the 0.1um to 0.15um thick. We can coat with other materials, such as Aluminium, Titanium, Gold and ITO..but specialist coatings means that we have to run a complete chamber full so there will be minimum order quantities required, varying between 5 and 30 plates depending upon the plate size

- Chrome Reflectivity

-

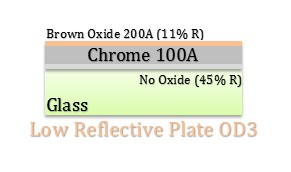

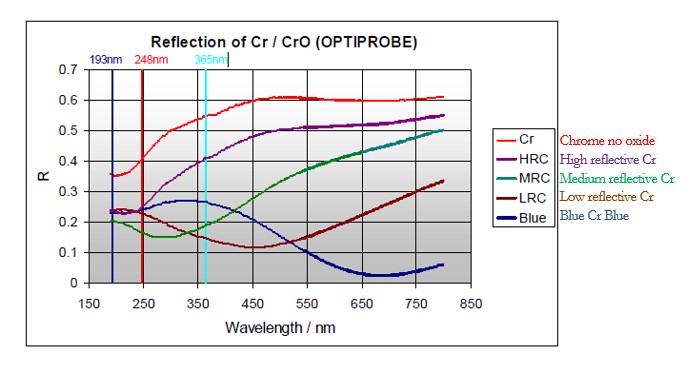

The chrome that is coated on the plate would normally have a bright mirror-like finish to it, reflecting at about 75%. We need to protect this surface with an oxide coating (chrome oxide) , and this oxide is applied to not only protect the surface but also to change the reflectivity of the plate. Our standard product is a LRC (Low reflective Chrome) which reflects around 12% in the UV wavelengths and therefore is most suitable for applications using Mask Aligners and other UV exposure equipment. Low Reflective refers to the oxide coating which is applied to the top surface of the chrome plate. This oxide makes the surface appear “yellow/gold” to our eyes when we hold the plate in a way that the light reflects off it. Because this oxide is applied after coating, the underneath surface of the chrome – the surface that sits against the glass – will remain bright/shiny with a mirror like finish.

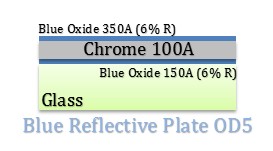

We stock a small amount of “blue” reflective chrome. This is low reflective when using the plate in the visible spectrum, so is the best solution for components that are used optically. With this material, our default is to have the oxide applied to both surface of the chrome so it will appear identical when looked from the front (chrome side) or the back (glass side)

We also have a small range of High Reflective chrome. This chrome has an oxide coating over the surface, so is not as reflective as the "underneath" side of the plate, but still reflects high at around 50%

Different "colours" of chrome will reflect at different amounts, depending upon the wavelength that is used. As standard, we stock Low Reflective Chrome in all sizes. We have a small selection of Blue Chrome plates and a very small range of High Reflective plates. Note that Blue oxide coating can be “tuned” to different wavelengths, such as 650nm, 800nm, 850nm etc (MOQ applies)

- Light Transmission

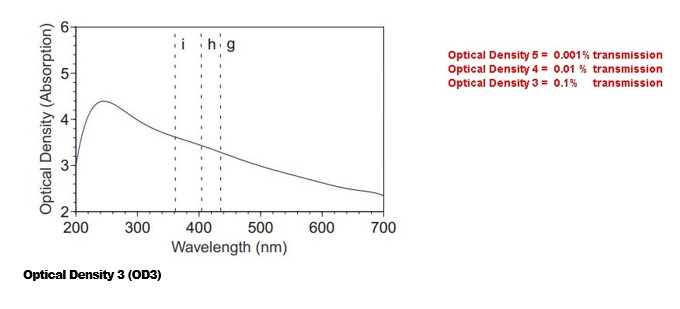

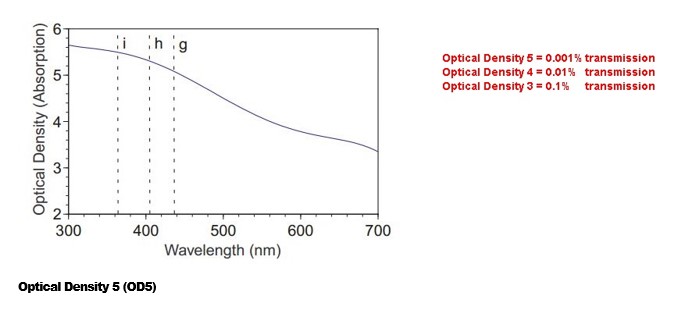

- Although the chrome coating is normally supposed to be "opaque" and block light totally, the rules of Physics mean that some light wavelengths will always transmit through the chrome coating. The amount of transmission is very low, but it will vary according to the thickness of the chrome and the wavelength of the light. The below charts show the Optical Density (transmission of light) through 2 different thicknesses of chrome plate. Our standard products for most smaller plates that we hold in stock are OD3... that’s to say that they are guaranteed to be higher than optical density 3 when used in the wavelength range of 350-450nm (UV exposures). Plate sizes above 7” in size are generally stocked using a thicker chrome, whereby a density of 5 or more is guaranteed in the UV range of wavelengths.