CLEANING CHROME GLASS

The benefit of using a glass-based product is that they are much easier to clean – the glass and chrome surface can be treated with a variety of chemicals, with no detriment to the image or surface quality. However, it is important not to use IPA or Acetone to clean the plate, especially where fine features are concerned, because this may lift the chrome off the plate.

The method used for cleaning the plate will depend upon the contaminants that are present –light soiling with greasy fingerprints could probably be removed with a simple wipe, whereas more stubborn contaminates that have been picked up from the contact/exposure process may have to follow a more rigorous procedure detailed here.

CLEANING PHOTORESIST FROM GLASS

If you are using the glass pattern as a photomask in a mask aligner, and it is in contact direct with wafers covered in the photoresist, then from time to time you may have trouble removing the excess photoresist which has adhered to the surface of the photomask plate.

We have a special product formulated just for that – it is called “PCS 605 Photomask Cleaner” It is a non-hazardous water-miscible cleaner for critical photomask cleaning applications and may be used on a variety of delicate mask substrates including iron oxide, chrome, or emulsion without damaging the surface. For emulsion masks, use at 1/8 dilution.

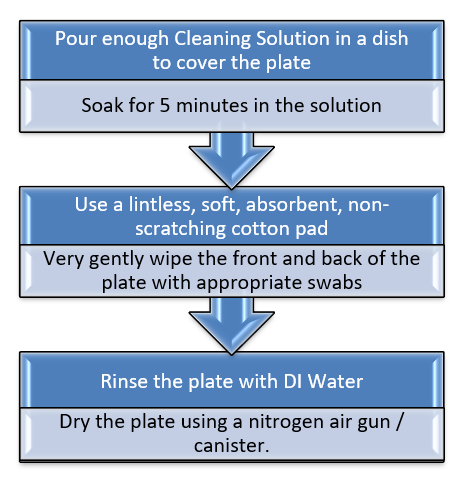

Prior to further processing, the photomask should be submerged in PCS 605 Photomask Cleaning Solution. Cleaning is enhanced by ultrasonic or megasonic agitation. Alternatively, manual scrubbing is effective. Care should be taken not to damage the part while scrubbing gently. It is recommended that a clean room foam wipe be used to maximize the cleaning effect of the solution.