Defects

For chrome patterns, the manufacturing specification of the raw materials, means that there may be minor defects that appear randomly across the material coatings. A manufacturing defect is a defect in a product that was not intended. Usually, these defects are cosmetic only, and often the defect causes no working problem with the design. We call these non-critical defects.

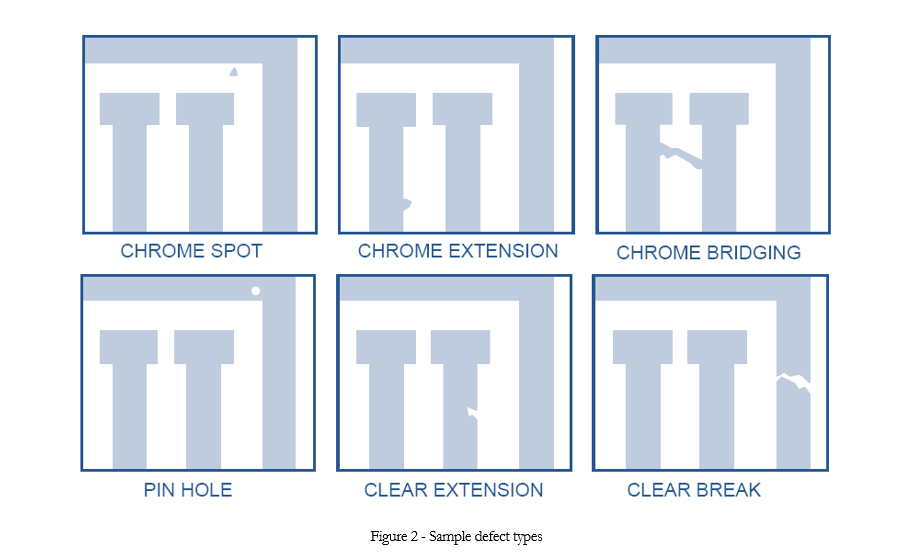

Critical defects are ones that could cause potential problems., and can take many forms such as a "pinhole" in what should be the chrome/emulsion part of the mask, or it can be a chrome/emulsion spot in the clear part of the mask (also referred to as 'shorts' or 'breaks'). A defect is any flaw affecting the geometry that violates the authorized specification for the order.

Furthermore, defects can be classed by the position in which they appear. We normally define the areas of a pattern as being the “Active Area” ( part of the area that has a direct bearing on the performance of the pattern) and the “Inactive Area” (text, borders, non-critical areas for example)

For all types of work, the customer must indicate the size of defects that will affect their process and render the pattern unusable. All defects which break these rules must be repaired, or if they cannot be repaired, the mask must be rejected and rewritten. Where no defect spec is given by the customer, we use our own internal standards (please ask for a copy).

There is also a class of defects known as cosmetic defects. These are defects that may not affect the pattern geometry but still may not be acceptable to the customer. Cosmetic defects include scratches on the chrome outside the array, damaged or partially removed the coating, contamination on the chrome, glass chips on the edge of the plate, etc.

The Customer Defect Specification Form is to be used by customers to inform us of their defect specifications. It may be supplied to cover every order within a given time frame or on a per-order basis. If the form is not submitted, our own internal specifications take over. These specifications will be used by our front-end engineers at the pre-inspection stage to assess if masks can be written before going into the writing phase, and customers will be informed where specifications are deemed to be unachievable.