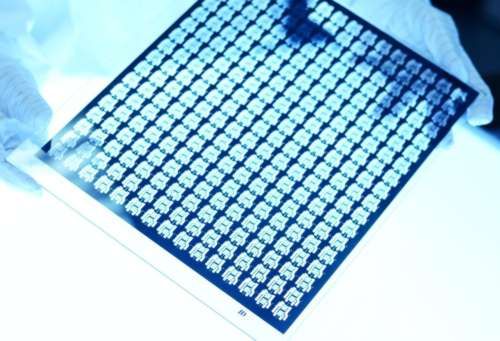

Emulsion Glass Photomask 17" x 0.090"

Emulsion Soda Lime Glass Photomask

17" x 17" x 0.090" (L x W x D)

430mm x 430mm x 2.3mm

EMULSION ON SODA LIME As well as offering emulsion on polyester film, we have a small range of emulsion on soda lime glass that is available. The emulsion coating is higher resolution than its polyester version so smaller features can be imaged, and emulsion brings a higher optical density with a black matte finish. However, the paring of soft emulsion on a hard glass surface means that this is even more susceptible to damage of the emulsion layer if handled incorrectly. This configuration is usually a cheaper alternative to Chrome when large sheet sizes are required

BASE MATERIAL

As standard products, these are available on Soda Lime glass with a photographic emulsion silver halide image exposed onto the surface. The finished product has a "black" effect on clear glass.

RESOLUTIONS

We can write masks at 3 different resolutions, called "classes". The higher the resolution, the better the qualtity. Please see the section SPECIFICATIONS to see the impact that class resolution has on dimensional accuracy and feature tolerances.

Class 1 : This represents a resolution that is equivalent to approximately 32k dpi . Although this resolution may resolve smaller features, we recommend keeping feature sizes above 60um as corner rounding is considerable. Edge sharpness and definition is acceptable for non critical design types, although designs with arcs/circles and lines running off 90 degree grid may show pixilation. NO features such as lines / circles / spots / squares below 50 um unless on a 'best effort' basis previously agreed with our technicians.

Class 2 : This represents a resolution that is equivalent to 64k dpi (previously known as High Resolution) . This resolution will resolve down to 30 micron lines and has good line edge qualities with only a small pixilation along edges. Corner rounding is below 3um but still visible. NO features such as lines / circles / spots / squares below 30um unless on a 'best effort' basis previously agreed with our technicians.

Class 3 : This represents our most common resolution for demanding, high precision photomasks. It is equivalent to 128k dpi (previously known as Super High Resolution) , and offers an excellent price / quality balance. This resolution will resolve down to 20 micron lines and has very good line edge qualities with no pixilation along edges, and corner rounding is kept to a minimum.

CAD FORMAT

Data formats listed above are only a small section of what is available. If your chosen format is not listed, please contact us for further information and clarification. We are also able to provide a full drafting service whereby we can create your designs from drawings and descriptions.

|

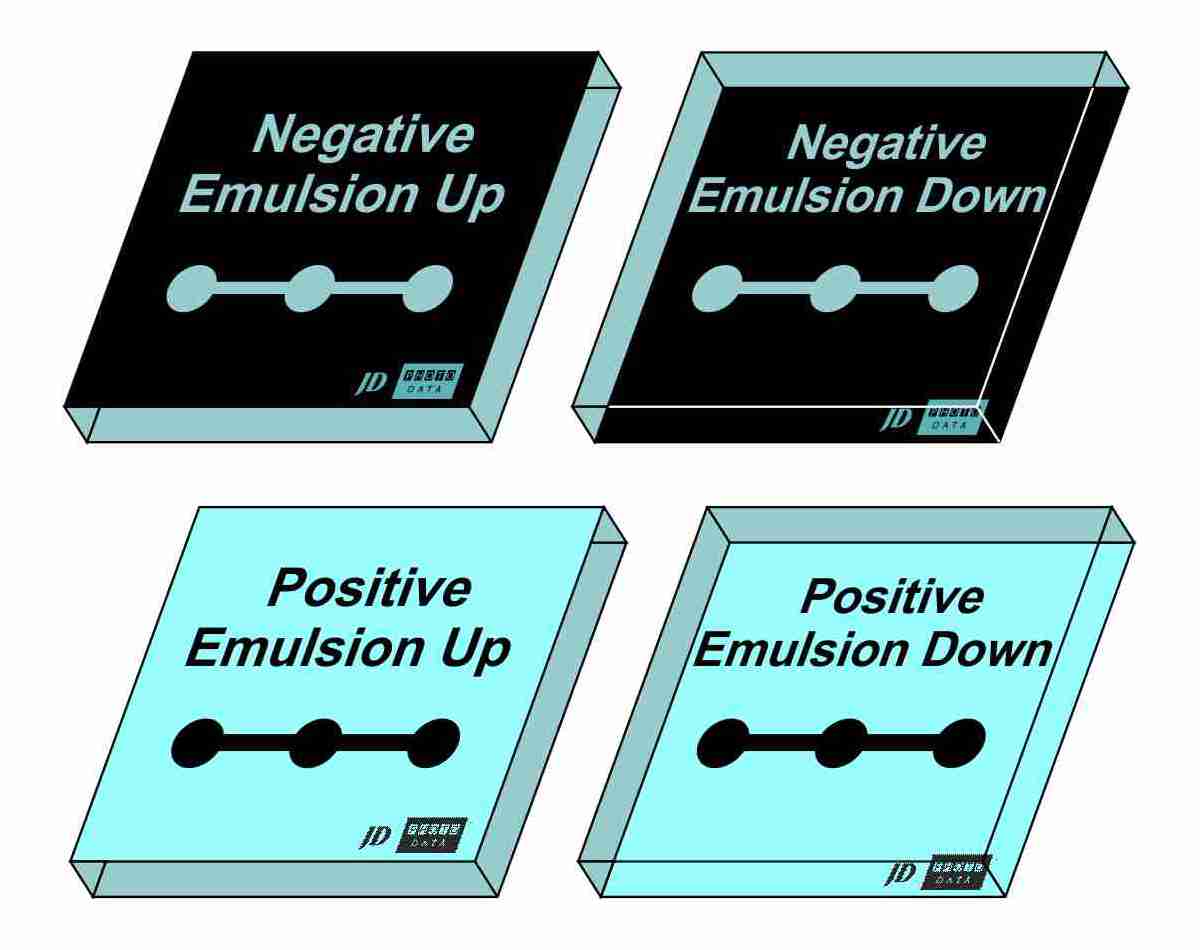

POLARITY Masks are normally referred to as Clearfield (positive) & Darkfield (negative) Positive means that the data you have drawn in CAD will be Chrome on the mask, with the background (the field) being clear glass. Negative is the opposite of this, where the items drawn on CAD will be clear and the background will be chrome. We also need to know which way round the mask has been designed on your screen. The easiest way to select this is to add some reference text (anything you like) to the design somewhere - maybe in the corner - and then specify if the text needs to be right reading or wrong reading. |

PRODUCTION SCHEDULE

For LARGE format photomask, our standard production turnaround is 14 days from receipt of the artwork, purchase order and related documents. We generally send checkplots with every order, and it is vital that these are replied to within a short delay in order that we can meet the schedule required. The production schedule assumes the original data package is correct and does not need to undergo revisions or changes. For large volume orders, or large photomasks on high resolutions, please enquire before ordering premium services.

Standard (14 days) : This is our standard service, and whilst we get 99% of orders shipped within this period, these are guidelines only and may change in periods of high demand. Where data packages are good, and all paperwork is completed promptly, we can often ship early. Any orders received after 1pm will assume day 1 to be the following day.

10 Days : A premium service. Any orders received after 10am will assume day 1 to be the following day

.

INSPECTION

Standard : We firstly inspect the piece by eye for flaws, design inaccuracies and contaminations. We also inspect a test coupon (placed in the bottom corner of the mask) for line width accuracy and edge definition. Next we measure the overall dimension of the mask, and record both of these measurements on our internal inspection records. Finally, we find the CD of the mask, measure that, record it, and also take a digital photo that is saved with the inspection log. We use Nikon MM40 at 900x magnification and an OGP ZIP 300 at 400 x magnifications for this.

Enhanced : In addition to the standard inspection process described above, we will then document them via a Certificate of Conformance which we supply with the mask. Tolerances are per our standard tolerances.

Full Certificate : By selecting this option during the ordering process, we will inspect upto 10 customer defined measurements, with customer supplied tolerances. You will need to send us a document, or a separate layer of the design, showing us where you want us to take the measurements from. There can be upto 10 positions defined by the customer. These dimensions are then programmed on the co-ordinate measuring system and the mask is compared to this unique program. A certificate of conformity is given if the mask passes the inspection process.

Please see the TECHNICAL sections, DOWNLOAD sections and FAQ for further information. If you still require clarification, pleas either email or click for LIVE SUPPORT.

SPECIFICATION

Emulsion Glass used for photo-masks have the following component layers: a soda lime glass base and a photosensitive emulsion layer (silver halide).

When we expose the plate in the imager, the light energy from the laser interacts with the silver halide crystals suspended in the coated gelatine layers. Development, a chemical process, converts exposed silver halide grains into metallic silver. The next step in the chemical process is fixation. The fixer stops development and removes the unexposed silver halide grains in non-image areas. Finally, the plate is washed/dried/cleaned and inspected.

The final result is a ‘black’ image coated on one side of the plate. The density of the emulsion is very high, typically Dlog of 4.5 – 5, giving it an excellent opacity to all common light sources.

One concern with emulsion glass is robustness. The Gelatine/Emulsion is relatively soft and must be handled carefully to avoid damage and scratches.

Our photo-masks are produced in conditions of 21deg C , and if dimensional accuracy is a concern when using the mask, then you must replicate these conditions in your own clean rooms and acclimatise the mask in these conditions for upto 4 hours before you intend to use it – only then can it be considered to be dimensionally accurate and stable.

FEATURE TOLERANCES

There are two different values that we specify for tolerances. The first is a ‘feature tolerance’, which equates to one specific feature (also known as CD or Critical Dimension). So, if part of your mask design has a 12um channel and this is a critical feature, you can use the table below to work out possible deviations to the channel width, depending upon which resolution you choose. As a rule, the higher the resolution, then the more accurate the individual feature size will be.

|

Resolution

|

Material |

Tolerance |

|

CLASS 1 |

Emulsion Soda Lime

|

60um +/- 6um |

|

CLASS 2 |

Emulsion Soda Lime

|

40um +/- 4um |

|

CLASS 3 |

Emulsion Soda Lime |

20um +/- 2um |

All figures above in Microns....

DIMENSIONAL TOLERANCES

The second tolerance that customers ask us about is that of overall dimensional tolerances. These refer to the tolerances over a distance greater then 5mm – in layman’s terms, people ask us ‘how accurate will the mask be’ and these guidelines should go somewhere towards providing the tolerances in overall dimensions ,depending upon the resolution chosen. Again, it goes without saying that the higher the resolution, then the more accurate the final mask.

Our photo-masks are produced in conditions of 21deg C , and if dimensional accuracy is a concern when using the mask, then you must replicate these conditions in your own clean rooms and acclimatise the mask in these conditions for upto 4 hours before you intend to use it – only then can it be considered to be dimensionally accurate and stable.

|

Resolution

|

Microns |

|

|

where L is measuring length in MM and the resulting |

|

CLASS 1 |

= 7 + (L * 0.008) um |

|

CLASS 2 |

= 5 + (L * 0.006) um |

|

CLASS 3 |

= 3 + (L * 0.004) um |

All figures above in Microns....

Example, at Class 3 resolution a 100mm line would have a tolerance of (3.0 + 0.4) = +/- 3.4um

WRITE AREA

The way that the blank materials are coated and handled during their manufacture, results in a "keep out" frame that is 10mm wide around the entire edge of the plate, with a 15mm “keep out” zone in the corners of the plate. We cannot accept to write critical features in this area, although it is possible to add non critical text and reference markers. If you need the design to be closer to the edge, we recommend selecting a larger plate size and then requesting that we cut it down to the required size after imaging process.

DEFECT SPECIFICATIONS

The customer may indicate the size of defects that will affect their process (defect spec). All defects which break these rules must be repaired, or if they cannot be repaired, the mask must be rejected and rewritten. The Customer Defect Specification Form is to be used by customers to inform us of their defect specifications. It may be supplied to cover every order within a given time frame, or on a per order basis. Where no defect spec is given by the customer, we use our own internal standards.

FAQ's

Q: What is the smallest feature that you can do ?

A: This depends upon the resolution that we image at, the tone of the mask, and most importantly the feature type (Spot, square, line etc). This all makes it very hard to give a figure, but as a very rough guide we can make 10-12um on an "everyday" basis with emulsion glass, and down to 8um and possibly below if we "hold it's hand through production".

Q: How accurate are the features, what tolerances do you work to ?

A: This is dependant upon the resolution that we image the mask at. The QUICK REFERENCE brochure in the DOWNLOADS section will give you a chart, specifying both feature and dimensional tolerances.

Q: What resolution should i pick ?

A: The higher the resolution, then the sharper the edges of the features, the smaller the features possible, the more accurate the features will be, the sharper the corners in of the features, and also the smoother the circles. Some customers will notice this difference straight away, some will hardly notice any difference. Every customer has different requirements and different priorities. If in doubt, chose a higher resolution to ensure your requirements are met, but we are happy to advise if you send us your database.

Q: What does the term POLARITY and FIELD mean ?

A: Polarity is the tone of the photomask. When you draw your photomask design, polarity determines whether the features on the mask are CLEAR or DARK on the final plate. The field refers to the background tone of the mask. So, a DARKFIELD mask would have the items you have drawn as CLEAR, with the background of the mask as DARK. Obviously this is the opposite for CLEARFIELD, where the field behind is clear and the design features are DARK. Remember, this is polarity or tone of the mask that we manufacture, and NOT the polarity of the wafer you are using. If used in contact lithography, the tone of the photoresist that you use will also affect which polarity to order.

Q: I've designed my mask with the wrong polarity - what do i do ?

A: We can use the original design file and simply reverse the tone of the mask. This is much easier than supplying new data.

Q: What is Right Reading, Wrong Reading and Mirrored.

A: Right Reading Chrome side Down is the most common way to describe a photomask that will be used for contact lithography. When you hold the mask in your hands with the chrome side facing down closest to the wafer, the image on the mask will be correct or how it should appear on the wafer. This is equivalent to Wrong Reading Chrome side Up. For us to make this happen we have to Mirror the image of your photomask before we write it.