Emulsion Specifications

This is a typical substrate used in the photographic process and forms the most common substrate in applications that involve general multiple exposures (such as PCBs, etching, printing etc). Polyester is excellent due to its low-cost nature but must be handled carefully and used in controlled environments if dimensional accuracy is required.

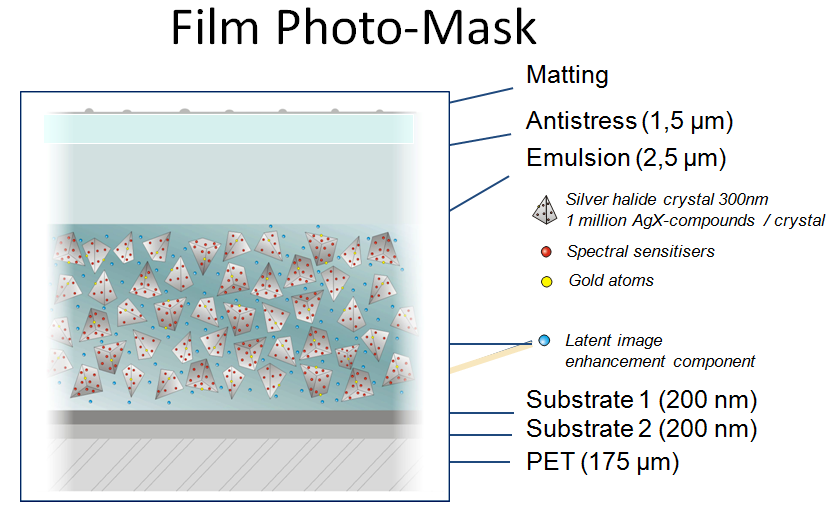

Films used for photo-masks have the following component layers: a plastic base, a photosensitive emulsion layer (silver halide) and a backing layer.

This plastic base is PET material and has a thickness of 0.18 mm. The emulsion layer is composed of gelatine and silver halide and other chemicals, which adds another 0.005 mm in total.

When we expose the film in the imager, the light energy from the laser interacts with the silver halide crystals suspended in the coated gelatine layers. Development, a chemical process, converts exposed silver halide grains into metallic silver. The next step in the chemical process is fixation. The fixer stops development and removes the unexposed silver halide grains in non-image areas. Finally, the film is washed/dried/cleaned and inspected.

The final result is a 'black' image coated on one side of the PET base. The density of the film is very high, typically Dlog of 4.5 - 5, giving it an excellent opacity to all common light sources.

Two concerns with emulsion film over glass are stability and robustness. Both the polyester and the gelatine absorb moisture and heat from their surroundings, and as such they undergo dimensional changes - quite considerably for some large-area films. The other problem with the Gelatine/Emulsion is that it is relatively soft and must be handled carefully to avoid damage and scratches.

Our photo-mask films are produced in conditions of 21deg C / 50% humidity, and if dimensional accuracy is a concern when using the polyester mask, then you must replicate these conditions in your own clean rooms and acclimatize the mask in these conditions for up to 8 hours before you intend to use it - only then can it be considered to be dimensionally accurate and stable. We strongly recommend using glass-based substrates where dimensional stability is a concern.