Film Punch

We have the ability to add very accurately punched holes to our films after manufacturing.

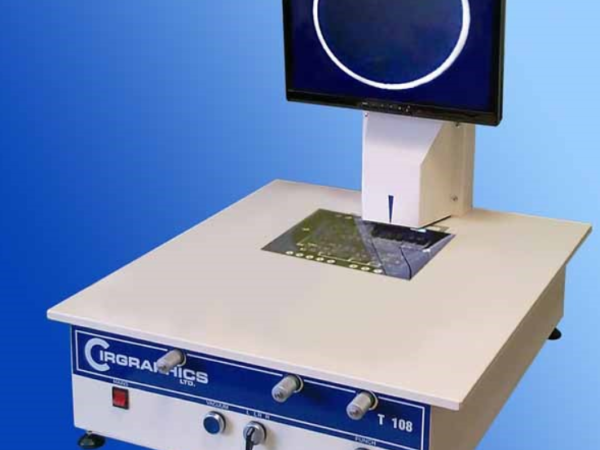

This is carried out on an optical registration system, using high magnification alignment. The films are imaged with a target – a simple solid round circle – to which the punch is optically aligned and then a hole cleanly punched through the film. Adding 2 holes on the same axis will then allow the film to be aligned to devices that have pins fitted to them.

Where multiple films are punched, this allows very accurate registration between the films when they are placed back-to-back. This is an ideal method for aligning films where double-sided etching is used.

The punched holes must be within a certain distance of the edge of the film - this is due to the "throat" size of the film punch. So for example, using the 6mm punch then the hole must be placed within 200mm of the edge of the film… so if you have a pattern that is 500mm x 500mm, it would be impossible to punch a hole in the centre.

The distance between holes along the edge – nor the number of holes - have no limitations. For alignment, we generally punch holes in pairs, although you can request as many as you need.

Adding a quantity of 1 “punched holes” to your basket will give you 2 punched holes in a film.