Greyscale Halftone Film 500 x 600

HALFTONE GREYSCALE FILM

508mm x 609mm x 0.18mm

Maximum Image: 488 x 589mm

This is a polyester photographic film greyscale , created using a halftone effect that is often used in printing technologies. Available upto 1000 lpi, with pixels down to 6um. it is ideal for graphics type of work, with large areas of varying tones of grey.

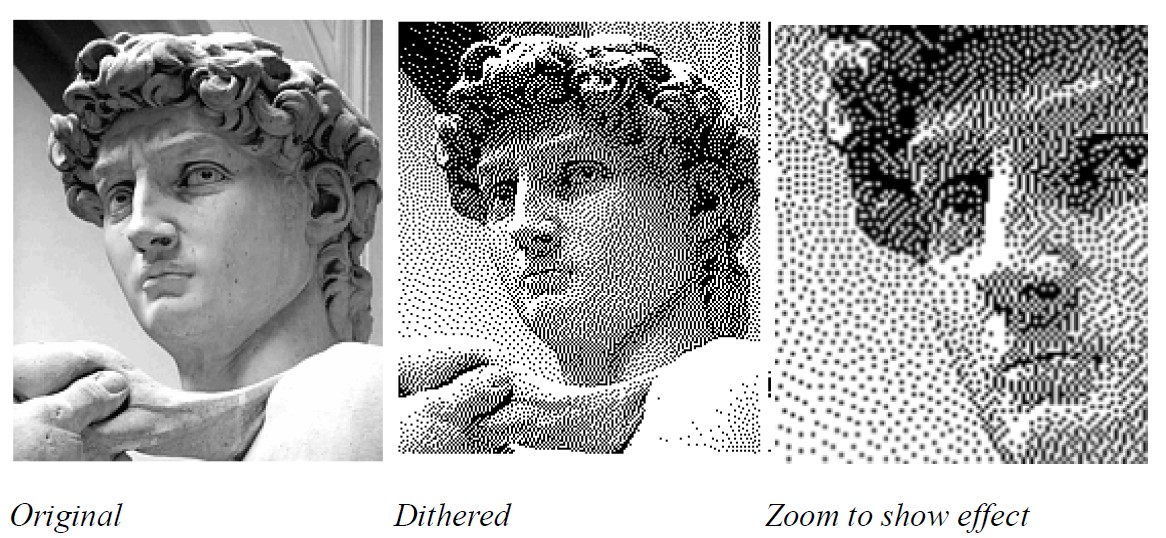

A greyscale halftone image is one where each pixel in the image represents a different rate of grey intensity. The general consensus is to use a range where 0% - totally clear and 100% is totally black. Our process is a binary one, whereby we can only image "black" pixels on clear film, so we cannot create a normal greyscale image as defined by "photography". However, we have a solution that works in the vast majority of cases, and that is pixelation or dithering to create a halftone.

By creating a halftone - part of the process is to make the pixel that creates the "grey" smaller than the lens (or eye) can resolve. In this manner, the lens will just see an overall grey tone rather than individual pixels. The halftone process uses dots of differing sizes (pulse-width modulation) and spacing (frequency modulation) to build up that image.

50% grey pattern @ 1000 LPI resolution, made up of 18um pixels

PIXEL AND RESOLUTION

The resolution of a halftone screen is measured in Lines_per_inch (lpi). This is the number of lines of dots in one inch, known as the screen ruling, The higher the pixel resolution of a source file, the greater the detail that can be reproduced. We have 4 standard resolutions that can be chosen, although you are free to choose any resolution LPI if you need a specific spatial frequency. For reference, a typical laser printer will print greytones at 65 LPI, and high quality professional book printing would be 150 LPI.

Below are guides to pixel sizes dependant on the resolution chosen. At 1000 LPI resolution, a 20% grey tone would be made up with a 13um black pixel on a clear background, where a 90% tone would be made up of a 6um clear pixel in a black area.

| Resolution | Dot Size um @ 10% | Dot Size um @ 20% | Dot Size um @ 50% | Dot Size um @ 70% | Dot Size um @ 90% |

| 250 LPI | 36 dark | 50 dark | 72 | 62 clear | 36 clear |

| 500 LPI |

18 dark |

25 dark | 36 | 31 clear | 18 clear |

| 750 LPI |

12 dark |

16 dark | 25 | 20 clear | 12 clear |

| 1000 LPI | 6 dark | 13 dark | 18 | 14 clear | 6 clear |

CAD FORMAT

Please tell us what format you will be sending. Data formats listed above are only a small section of what is available. If your chosen format is not listed, please contact us for further information and clarification. We are also able to provide a full drafting service whereby we can create your designs from drawings and descriptions.

|

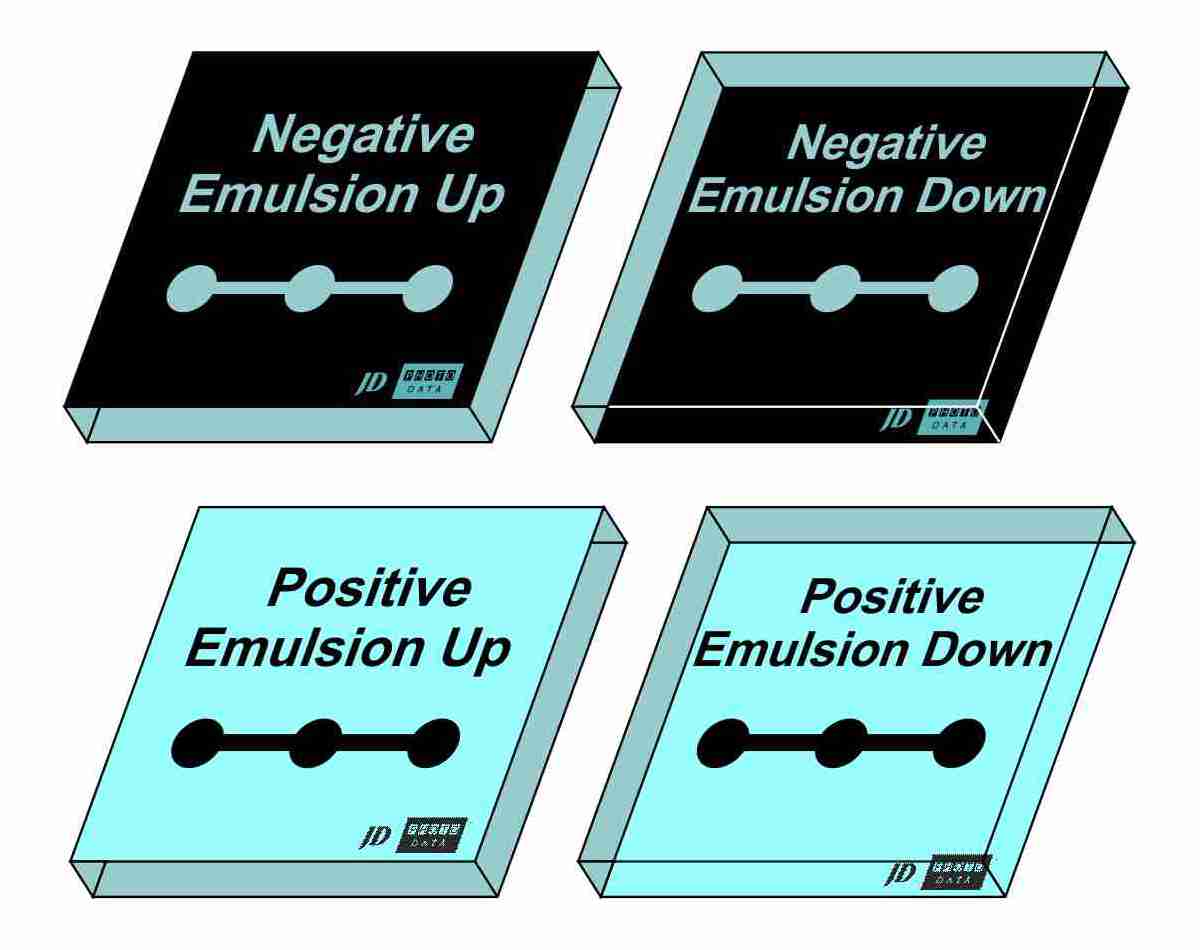

POLARITY Films are normally referred to as Clearfield (positive) & Darkfield (negative) Positive means that the data you have supplied Black on the film, with the background being clear film. Negative is the opposite of this, where the image supplied will be inversed and the picture will be clear and the background will be black.

|

PRODUCTION SCHEDULE

Our standard production turnaround is 3-4 days from receipt of the artwork, purchase order and related documents. We generally send checkplots with every order, and it is vital that these are replied to within a short delay in order that we can meet the schedule required. The production schedule assumes the original data package is correct and does not need to undergo revisions or changes. For large volume orders, or large photomasks on high resolutions, please enquire before ordering premium services.

Standard (3-4 days) : This is our standard service, and whilst we get 99% of orders shipped within this period, these are guidelines only and may change in periods of high demand. Where data packages are good, and all paperwork is completed promptly, we can often ship early.

Premium (2 Days ) : A premium service. A complete manufacturing package (data/instructions/order) must be with us by no later than 11.00am.

YOUR DRAWING NUMBER

Please let us know the CAD file name / number so that we can tie together the uploaded data and the order.

NOTES

Here you can inform us of any other requirements or specifications regarding the order.

Please see the TECHNICAL sections, DOWNLOAD sections and FAQ for further information. If you still require clarification, please either email or click for LIVE SUPPORT.

SPECIFICATION

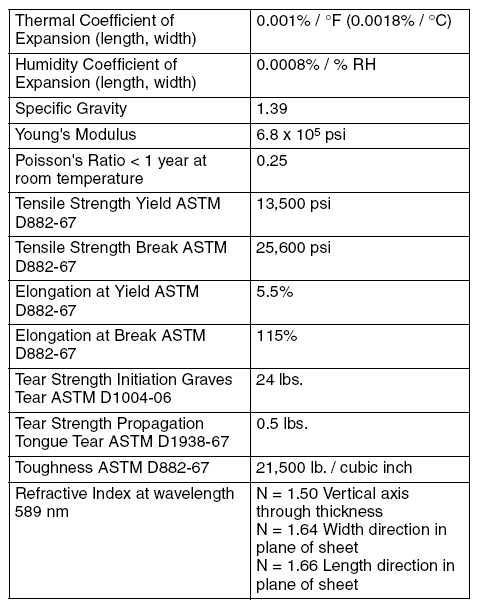

Polyester Film is a typical substrate used in the photographic process, and forms the most common substrate in applications that involve general multiple exposures (such as PCBs, etching, printing etc.). Polyester is excellent due to its low-cost nature, but must be handled carefully and used in controlled environments if dimensional accuracy is required.

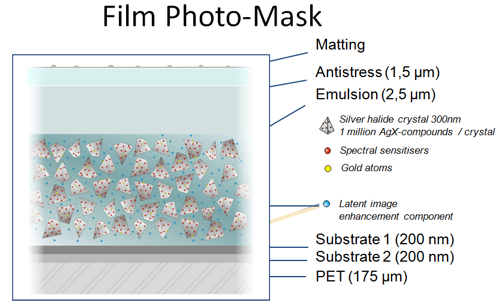

Films used for photo-masks have the following component layers: a plastic base, a photosensitive emulsion layer (silver halide) and a backing layer.

This plastic base is polyester material, and has a thickness of 0.18 mm. The emulsion layer is composed of gelatine and silver halide and other chemicals, which adds another 0.005mm in total.

When we expose the film in the imager, the light energy from the laser interacts with the silver halide crystals suspended in the coated gelatine layers. Development, a chemical process, converts exposed silver halide grains into metallic silver. The next step in the chemical process is fixation. The fixer stops development and removes the unexposed silver halide grains in non-image areas. Finally, the film is washed/dried/cleaned and inspected.

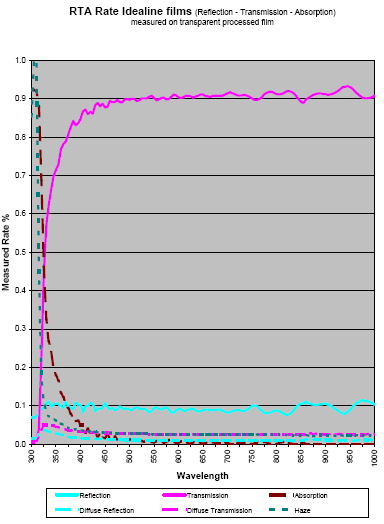

The final result is a ‘black’ image coated on one side of the polyester base. The density of the film is very high, typically Dlog of 4.5 – 5, giving it an excellent opacity to all common light sources.

Two concerns with emulsion film over glass are stability and robustness. Both the polyester and the gelatine absorb moisture and heat from their surroundings, and as such they undergo dimensional changes – quite considerably for some large area films. The other problem with the Gelatine/Emulsion is that it is relatively soft and must be handled carefully to avoid damage and scratches.

FAQ's

Q: What is the smallest feature that you can do ?

A: This depends upon the resolution that we image at, the material that we use, the tone of the film, and most importantly the feature type (Spot, square, line etc). This all makes it very hard to give a figure, but as a very rough guide we can make down to 5=6um

Q: What resolution should i pick ?

A: The higher the resolution, then the sharper the edges of the features, the smaller the features possible, the more accurate the features will be, the sharper the corners in of the features, and also the smoother the circles. Some customers will notice this difference straight away, some will hardly notice any difference. Every customer has different requirements and different priorities. If in doubt, chose a higher resolution to ensure your requirements are met, but we are happy to advise if you send us your database.

Q: What does the term POLARITY mean ?

A: Polarity is the tone of the film, and in layman's terms it is what you might call Positive and Negative. When you draw your design on your computer, you need to decide if the objects that you draw are going to be opaque on the film- and therefore to block the light - or transparent areas on the film. It's best to always think of the data that you draw either being positive data, or negative data.

Q: I've designed my image with the wrong polarity - what do i do ?

A: We can use the original design file and simply reverse the tone of the mask. This is much easier than supplying new data.