Write Areas

There are limitations to the area of the substrate that we can pattern – depending upon the substrate type used and the size of that substrate The limitation with hard metal products such as chrome is due to the way that the materials are manufactured – there is a fringe of photoresist around the edges of the plate where we cannot add any pattern; whereas the limitation with film substrates is much less stringent and comes from handling through the automated process.

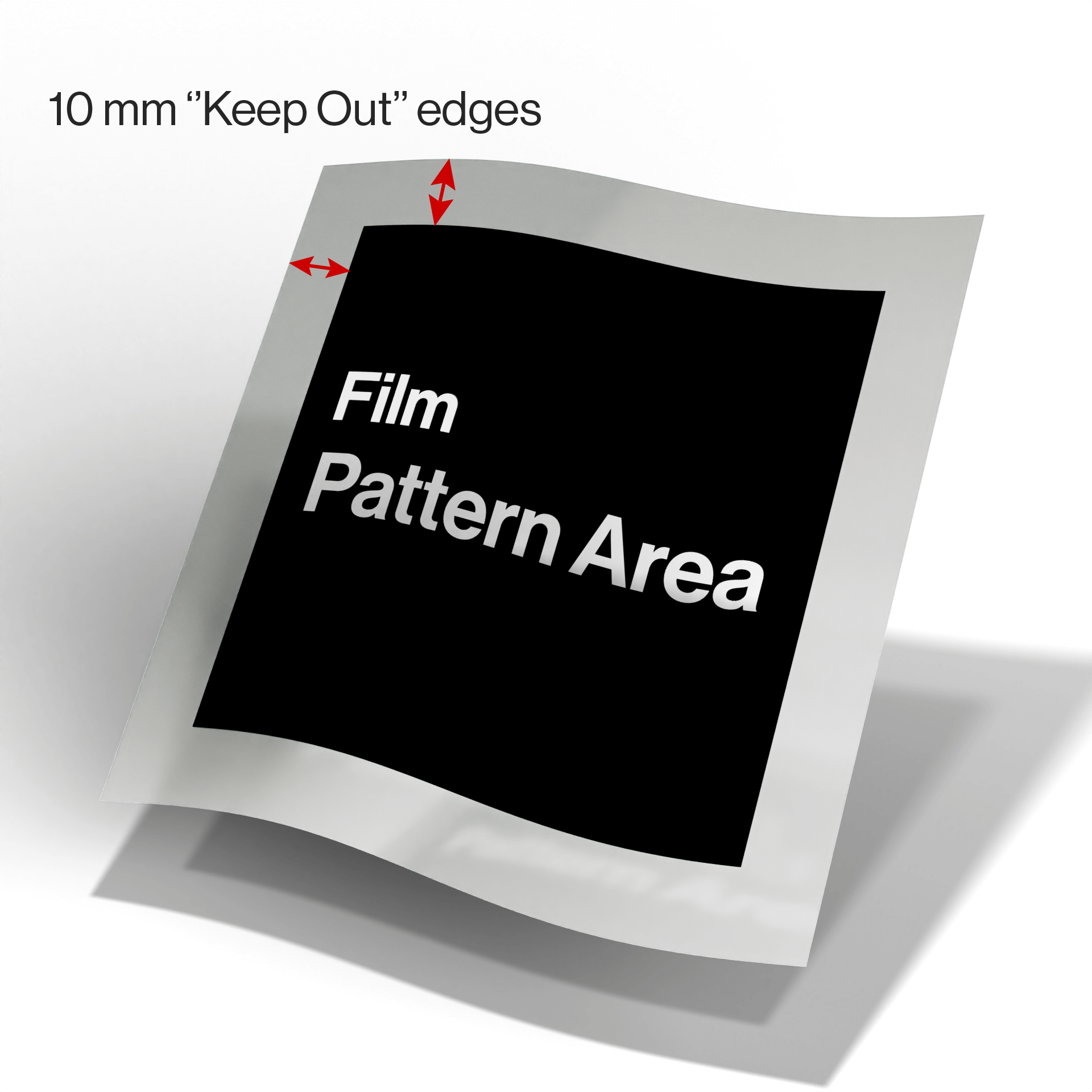

FILMS

The unexposed films are fed onto the laser imager. A vacuum is drawn down to hold the film in place, and then imaging begins. The slight variation in film positioning, along with the automated handling through the processing stages, means that we don’t allow any part of the image to be within 10mm of the edge of the film. We call this the “keep out” area.

GLASS

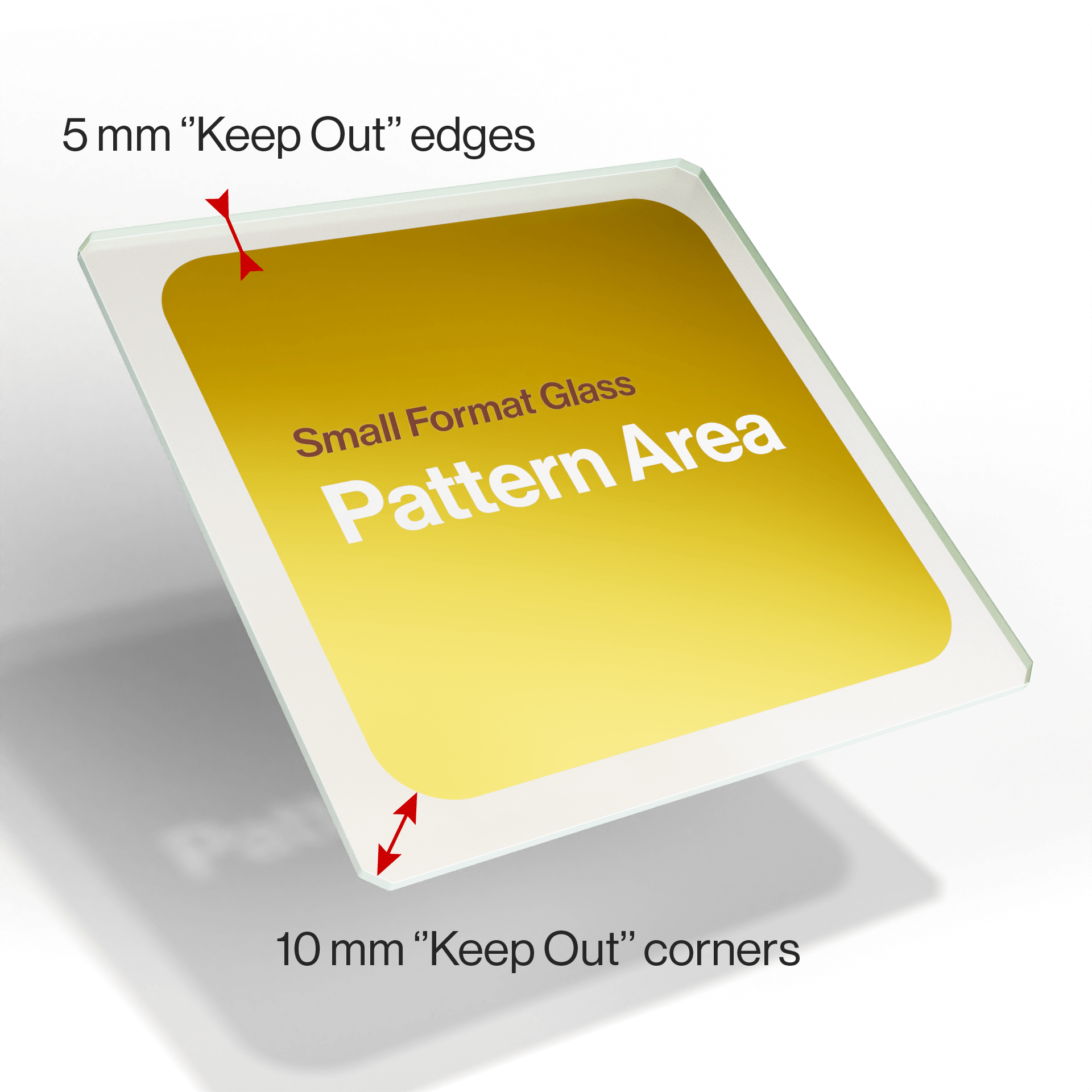

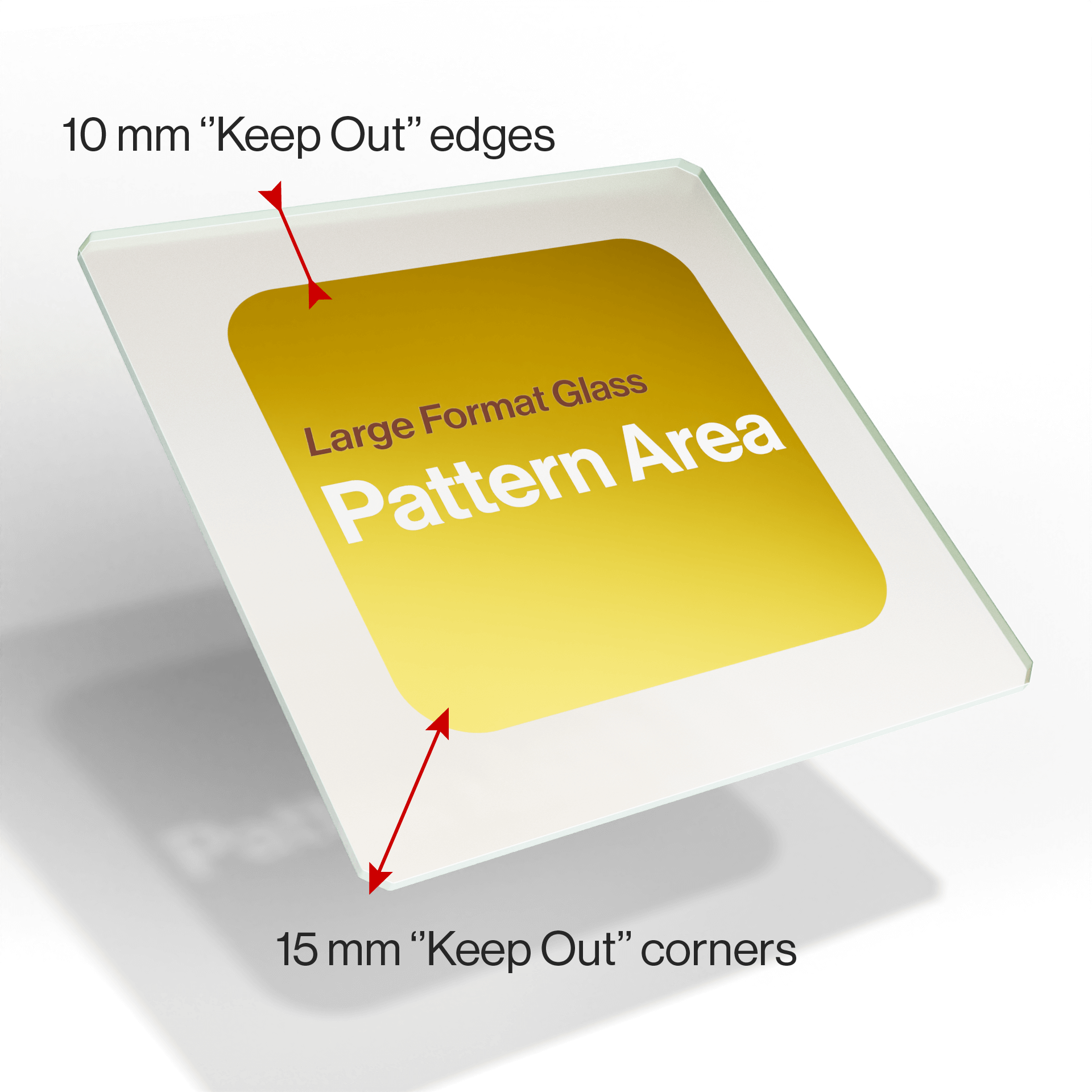

The glass plates are hand placed onto the imager bed by hand, and they are then scanned for size and shape automatically by the laser head. This allows much more accurate positioning of the data to the plate; however, the way that the materials are manufactured means that there is a “quality area”, and also a “keep out” area.

If your product is using a standard, full-size blank (the master sheets that we hold in stock), then the coatings do not go up to the very edge of the plate, so the pattern area must be smaller than the plate size.

If yours is a custom size, then this normally does not apply because we make the pattern first in the center of the master plate and then we cut it down to size afterward, meaning that the pattern can be much closer to the edge.

The “pattern area” is an area central to the master plate. Everything that is critical must be within this area. We also have a “keep out” area that no pattern can be within because there is no coating in this area so patterns will not appear here. The size of the “keep out” depends on whether it is a small format blank plate (<228mm) or a large format glass plate.