Large Format Chrome Resolutions

The following information refers to chrome-coated glass plates bigger than 227mm in size.

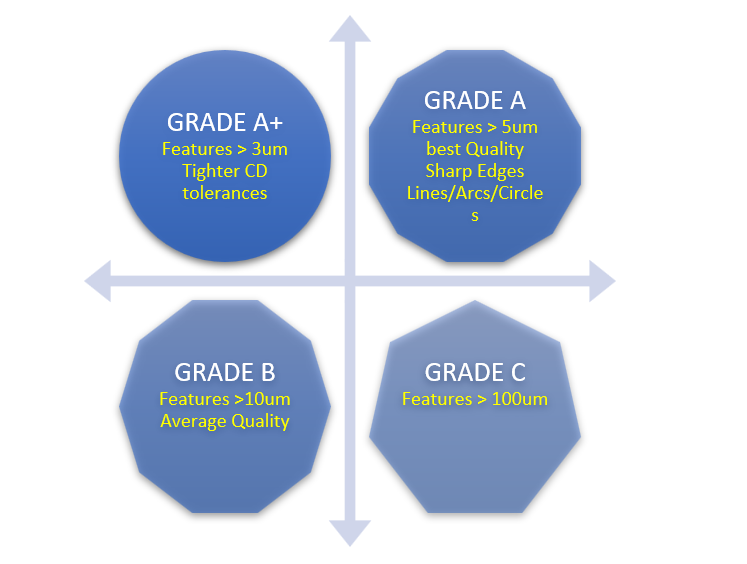

CHOOSING RESOLUTIONS

GRADE C : Feature sizes are approximately 100um and above, and the linewidth tolerance is +/- 3um. Edge sharpness and definition is acceptable for non critical design types, although designs with arcs/circles and lines running off 90 degree grid may show slight pixilation. This is our lowest resolution.

GRADE B : This resolution is to be used for features > 10um, or where linewidth tolerances can vary by +/- 1um. It has good line edge qualities with only a small pixilation along edges. Corner rounding is good, but still visible. This is our medium resolution.

GRADE A : This represents our most common resolution for demanding, high precision photomasks. It offers an excellent price / quality balance. This resolution will resolve down to 5 micron lines and has very good line edge qualities with no pixilation along edges, and corner rounding is kept to a minimum. Line width tolerances are +/- 0.5um. We have the possibility (GRADE A+) for special processing to bring the minimum feature and tolerance down further to 2um +/- 0.3, but this involves considerable extra processing and prices will change. Prices for below 5um can be given after submitting the design.

FEATURE TOLERANCES

There are two different values that we specify for tolerances. The first is a ‘feature tolerance’, which equates to one specific feature (also known as CD or Critical Dimension). So, if part of your mask design has a 12um channel and this is a critical feature, you can use the table below to work out possible deviations to the channel width, depending upon which resolution you choose. As a rule, the higher the resolution, then the more accurate the individual feature size will be.

All figures above in Microns....

DIMENSIONAL TOLERANCES

The second tolerance that customers ask us about is that of overall dimensional tolerances. These refer to the tolerances over a distance greater than 5mm – in layman’s terms, people ask us ‘how accurate will the mask be’ and these guidelines should go somewhere towards providing the tolerances in overall dimensions, depending upon the resolution chosen. Again, it goes without saying that the higher the resolution, then the more accurate the final mask.