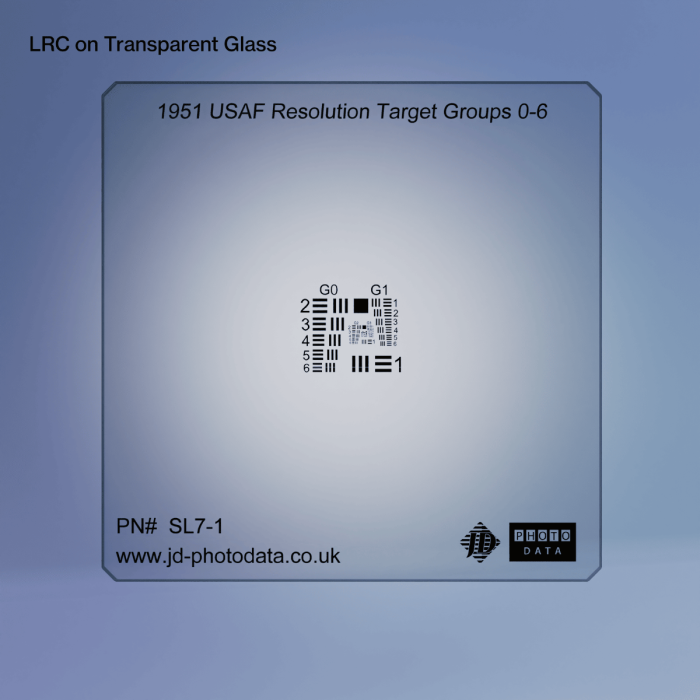

SL7 USAF 1951 Test Target

USAF 1951 - for calibration of imaging devices

High resolution chrome markings

Transparent glass or white glass

A resolution test pattern conforming to MIL-STD-150A standard, set by US Air Force in 1951. It is still widely accepted as the default pattern to test the resolving power of optical imaging systems such as microscopes, cameras and image scanners. The pattern consists of groups of three bars (small Ronchi rulings) with dimensions from big to small. The largest bar the imager cannot discern accurately is the limitation of its resolving power.

CONFIGURATION

- Material: Chrome on Transparent Soda Lime Glass, 1.5mm thick , available as 3" (75mm)

- Material: Chrome on White Glass, 1.25mm thick , available as 4" (100mm)

PATTERN DESCRITION

Chrome on Glass - Standard resolution

Includes groups 0-6 , with line width tolerance of +/- 0.8um

Chrome on Glass - Medium resolution

Includes groups 0-7 , with line width tolerance of +/- 0.4um

Chrome on Glass - High resolution

Includes groups 0-8 , with line width tolerance of +/- 0.2um

Polyester Film - Standard resolution

Includes groups 0-4 , with line width tolerance of +/- 4um

Polyester Film - High resolution

Includes groups 0-6 , with line width tolerance of +/- 2um

LINE PAIR DIMENSION

This chart is available as Low Reflective Chrome on Glass as the standard product, but also available on Polyester Film. The COG (Chrome on Glass) version contains elements 0-6 for the standard resolution chart, and groups 0-8 for the highest resolution, whereas the Polyester Film version has groups 0-4 for the standard resolution and groups 0-6 for the high resolution.

| Width of 1 line in micrometers in USAF Resolving Power Test Target 1951 | |||||||||

| Group Number | |||||||||

| Element | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| 1 | 500 | 250 | 125 | 62.5 | 31.25 | 15.63 | 7.81 | 3.91 | 1.95 |

| 2 | 445.45 | 222.72 | 111.36 | 55.68 | 27.84 | 13.92 | 6.96 | 3.48 | 1.74 |

| 3 | 396.85 | 198.43 | 99.21 | 49.61 | 24.8 | 12.4 | 6.2 | 3.1 | 1.55 |

| 4 | 353.55 | 176.78 | 88.39 | 44.19 | 22.1 | 11.05 | 5.52 | 2.76 | 1.38 |

| 5 | 314.98 | 157.49 | 78.75 | 39.37 | 19.69 | 9.84 | 4.92 | 2.46 | 1.23 |

| 6 | 280.62 | 140.31 | 70.15 | 35.08 | 17.54 | 8.77 | 4.38 | 2.19 | 1.1 |

| Number of Line Pairs / mm in USAF Resolving Power Test Target 1951 | |||||||||

| Group Number | |||||||||

| Element | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| 1 | 1 | 2 | 4 | 8 | 16 | 32 | 64 | 128 | 256 |

| 2 | 1.12 | 2.24 | 4.49 | 8.98 | 17.96 | 35.9 | 71.8 | 143.7 | 287.4 |

| 3 | 1.26 | 2.52 | 5.04 | 10.08 | 20.16 | 40.3 | 80.6 | 161.3 | 322.5 |

| 4 | 1.41 | 2.83 | 5.66 | 11.31 | 22.63 | 45.3 | 90.5 | 181 | 362 |

| 5 | 1.59 | 3.17 | 6.35 | 12.7 | 25.4 | 50.8 | 101.6 | 203.2 | 406.4 |

| 6 | 1.78 | 3.56 | 7.13 | 14.25 | 28.51 | 57 | 114 | 228.1 | 456.1 |

BASE MATERIAL

This chart is available as Low Reflective Chrome on Glass as the standard product, but also available on Polyester Film. The COG (Chrome on Glas) version contains elements 0-6 for the low resolution chart, groups 0-7 for the medium resolution chart, and groups 0-8 for the highest resolution, whereas the Polyester Film version has groups 0-4 for the standard resolution and groups 0-6 for the high resolution.

TURNAROUND

Our standard production turnaround is 5 days from receipt of order. We can offer faster services if required for more urgent orders.

INSPECTION

STANDARD: We inspect the piece by eye for flaws, design inaccuracies and contaminations. We measure the design to check that it conforms to the specifications, and record both of these measurements on our internal inspection records. Finally, we find the CD of the mask, measure that, record it, and also take a digital photo that is saved with the inspection log. We use Nikon MM40 at 900x magnification and an OGP ZIP 300 at 400 x magnifications for this.

CERTIFIED: In addition to the standard inspection process described above, we will then document them via a Certificate of Conformance - or measurement certificate - which we supply with the target. Tolerances are per our standard tolerances.

Please see the TECHNICAL sections, DOWNLOAD sections and FAQ for further information. If you still require clarification, please either email or click for LIVE SUPPORT.

MATERIAL SPECIFICATION

Soda Lime Glass is the most common substrate used for masks, due to its good quality/price ratio. The glass is optically good, very flat and has no imperfections. If used in a photo-lithographic process, glass can be used with a very wide variety of light sources from 350nm upwards, with an excellent UV transparency. Soda Lime glass has a thermal co-efficient expansion of 93 (10-7) which is approximately 10 ppm (parts per million) , and a transmittance value of 88% at 375-450nm, with a glass flatness class of 5um for the smaller plates and 10um for the larger plates. Some of the very big plates of 14" and above, may have a bigger flatness tolerance.

- Soda Lime Optical transmission of visible light = 88%

- Soda Lime Optical transmission of visible light = 375nm

- Soda Lime thermal expansion co-efficient = 10ppm

Polyester Film is a typical substrate used in the photographic process, and forms the most common substrate in applications that involve general multiple exposures (such as PCBs, etching, printing etc.). Polyester is excellent due to its low-cost nature, but must be handled carefully and used in controlled environments if dimensional accuracy is required. Films used for photo-masks have the following component layers: a plastic base, a photosensitive emulsion layer (silver halide) and a backing layer. This plastic base is polyester material, and has a thickness of 0.18 mm. The emulsion layer is composed of gelatine and silver halide and other chemicals, which adds another 0.005mm in total.

- Polyester Film Optical transmission of visible light = 85%

- Polyester Film Optical transmission of visible light = 395nm

- Polyester Film thermal expansion co-efficient = 18ppm per 1 deg C Temperature, 9ppm per 1% humidity

FREQUENTLY ASKED QUESTIONS

Q: The pattern doesnt represent what i need - can we alter it as a special design?

A: Yes ....The patterns here are standard products, but we can certainly transfer almost any design to the slide (Note the price will change accordingly)

Q: How long from order to dispatch?

A: Typically we have these products in stock on the shelf - however, it may take upto 5 days before they are dispatched. If you need the product more urgently, please contact us direct and we will do our best !

Q: Can you send me a scaled picture showing the detail in higher resolution?

A: Certainly, we have higher resolution graphics that we can email you. Please contact us via the Live Support or by Email.

Q: Can I have different materials?

A: Yes. Our standard products are Low Reflective Chrome on Soda Lie glass or Polyester Film - but we can offer different base material (Quartz, Borofloat etc) and different masking materials (Aluminium, ITO, Gold etc), as well as simply different thicknesses of glass. There will be minimum order quantities for most of these special materials.