VisualCAM Assembly Programming

Full “top-of-the-line” system.

Complete Manufacturing Engineering CAM software package

VisualCAM is a powerful Manufacturing Engineering CAM software package that addresses the wide-ranging needs of EDA professionals. For the PCB layout engineer VisualCAM offers a complete set of Design Verification features. If you are a Bare-Board PCB engineer there is a full range of Manufacturing Verification and Tooling features available. Finally VisualCAM rounds out its capabilities by offering Loaded-Board PCB engineers an array of Assembly Processing capabilities not typically found within competitive products.

|

|

Design Verification: Verification of your design data is a critical step before submitting your job for production. Today's product complexities require PCB layout engineers to push spacing limits while laying out their board designs. Tighter tolerances can mean more expensive bare-boards, and thus the risks of scrap become more expensive as well--especially if the problems are not identified until after assembly. VisualCAM provides you with a Dynamic DfM Analysis Suite that offers 75+ Design and Manufacturing checks. A blend of traditional design related checks, like track-to-track and track-to-pad, as well as manufacturing checks, like acid traps and copper slivers, can be found within VisualCAM. Rounding out your design verification experience is VisualCAM's graphical netlist comparison with pin-point error detection. Compare your data set against any IPC-D-356 netlist, or use netlist information extracted from ODB++ or PADS ASCII files, and quickly zoom to any shorts or opens in the workspace. |

|

|

Manufacturing Verification/Tooling: As mentioned above VisualCAM provides a Dynamic DfM Analysis Suite that provides both design and manufacturing related checks. The ability to save and load different rule sets allows you to verify your data against your original design spacing rules, or against your manufacturer's spacing rules. Bare-board PCB engineers and PCB layout engineers alike appreciate the more robust checking features found within VisualCAM, versus those found within traditional CAD tools. VisualCAM also helps you go beyond verification and allows you to complete your final manufacturing-related tasks with automated features like solder mask and paste mask generation. Complete production tooling can be generated using VisualCAM's Advanced Panelization capabilities. You can create unlimited panel templates to accommodate a wide range of standard panel sizes. Advanced Panelization will even let you step single designs or multiple designs within the same panel frame. Venting and thieving are fully automated and user-defined as well. VisualCAM can finalize any manufacturing process flow with a robust set of NC drill and mill capabilities, including functions such as drilled text, drilled slots, user-defined break tabs, and one of the most efficient sort engines in the industry. |

|

|

Assembly Processing: There are many powerful tools on the market that are adept at extracting component footprint information from intelligent sources such as FATF, ODB++, GenCAD, or even your source CAD system's database. But what if you need to generate an assembly program and all you have to work from is Gerber data? While VisualCAM is designed to work on "intelligent" data formats like ODB++, ODB++ XML, or IPC-2581 data formats, it can still operate on traditional Gerber and NC data as well. Because of this, VisualCAM is one of the only manufacturing engineering software packages that can offer you five different automated methods to reverse engineer component footprint information from Gerber data, for the purpose of assembly pick-and-place programming. Depending on the data available to you at the time of processing, you can complete a component footprint identification process in as little as a few seconds. Even when reverse engineering interactively, most jobs can still be completed in just a few hours. You can even save and load footprint libraries, allowing you to build master libraries to help keep your output consistent. There is support for both component footprint fiducials, as well as board-level fiducials. When you complete your processing, you can output the data to a variety of formats: IPC 2581, ASCII, FATF, ODB++, ODB++ XML, or GenCAD. |

Regardless of your role within the design or manufacturing process, you can use VisualCAM to ensure the production of high-quality PCBs. Add flexible pricing, convenient and responsive customer support, and you have an unbeatable manufacturing engineering CAM software package.

Please see the TECHNICAL sections, DOWNLOAD sections and FAQ for further information. If you still require clarification, pleas either email or click for LIVE SUPPORT.

SPECIFICATION

- IBM PC-compatible with at least a 1 GHz Pentium CPU

- For best graphics display, a 17" or larger monitor with at least 1280 x 1024 resolution is recommended.

- At least 512 MB of RAM and 30 MB of hard disk space

- Gerber 274-D & 274-X

- Fire 9XXX

- Barco DPF

- DXF (AutoCAD 2000)

- HPGL & HPGL/2

- ODB++

- ODB++ (X)

- IPC-2581 (OffSpring)

- CAM350 v8.X (import)

- PADS ASCII (import)

- Excellon & Excellon 2

- Sieb & Meyer

- Takeuchi

- IPC-D-350 (export)

- IPC-D-356 & IPC-D-356A

- PostScript (export)

- Bitmap (export)

FAQ's

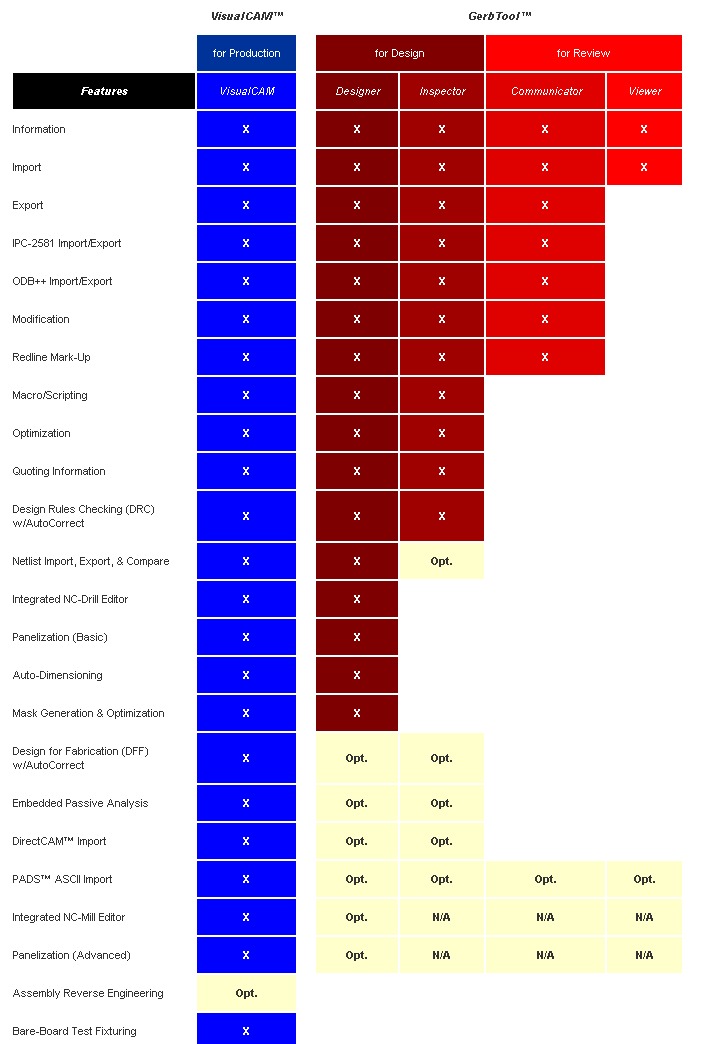

Q. What are the differences between the available versions ?

A. GerbTool comes in 3 "flavours". Each version has added functionality and features, however they are all based around the same platform and graphical interface, so it is easy to swap from one to another. The comparison chart in the SPECIFICATIONS tab will give you a guide to the features.

Q. What if a buy a version, and then need extra features later?

A. Dont worry, you can simply pay the difference between the 2 product levels, and upgrade with a simple key change. You will need to be on a current support contract.

Q. Why do I need a new access code every 365-days?

A. There are three types of licensing :

- Software License (single user node-locked, no hardware key)

- Hardkey License (single user node-locked, with hardware key)

- Floating License (single or multi user, with or without hardware key)

Due to the disdain of hardware keys by most users, WISE uses the Software Licenses method by default for its single-user node-locked installations. In order to afford some protection to WISE from potential improper use, we only issue a 365-day license in this environment. The license is not linked to maintenance and will be renewed perpetually. Like anything, there are pros and cons to this: the "pro" of not having a hardware key to contend with thus leads to the "con" of having to renew your license every 365-days.

For those users that do not like having to renew their licenses and/or wish to have the flexibility of moving their license to other machines, or taking the license home to work from another machine, you might want to consider using a Hardkey license. A hardware key can be provided for a nominal fee, and you will receive a permanent license for that key. You are then free to move the software around and not have to worry about your license timing out at the wrong time. The hardware keys attach to USB ports.

Q. I downloaded an evaluation copy. Can I get a temporary, full license?

A. Yes, you simply need to request a license (note that we can only provide temporary licenses for the most recent versions of VisualCAM and GerbTool).

- After performing a Nodelocked installation, start the application. It will open in Demo mode, and display a message box with an opportunity to immediately request an activation code.

- To request an acitvation code, click on the Request Activation Code button. The License Activation Request Wizard appears. Click the Next button.

- Your name, e-mail address, phone, and fax are required to receive an Activation Code. Use “Demo” for the serial number. Complete the Registration Information, and click the Next button.

- If you have any additional information that you would like to add to the license request, type it in the Notes field, and click the Next button.

- Indicate whether you want your license request sent directly to WISE Software by e-mail (preferred), printed (to send a fax), or saved as a text file that can then be included as an e-mail attachment. Our fax number is (503) 554-1220 and the e-mail is licenses@wssi.com.