What is a Photomask?

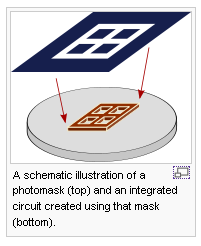

A photomask is an opaque plate or film with transparent areas that allow light to shine through in a defined pattern. They are commonly used in photolithography processes but are also used in many other applications by a wide range of industries and technologies. They are made on Soda Lime glass, on Fused Silica (Quartz) and even on Polyester Film. The mask acts as a template and is designed to optically transfer patterns to wafers or other substrates in order to fabricate devices of all types.

Current lithographic tools project light through a photomask and a high aperture lens. The intensity of the light casts an image of the pattern on the photomask onto a substrate, such as a silicon wafer coated with a light sensitive material called photoresist. Using negative photoresist, the unexposed, or masked, portion of this material is then removed so it can either be etched to form channels or be deposited with other materials. (The process is reversed using positive photoresist.)

Photomasks, requiring sophisticated manufacturing techniques and complex mathematical algorithms to design, are at the forefront of the microminiaturization of chips, enabling more functionality to be embedded within a smaller area. This trend in making devices as powerful and as small as possible facilitates the proliferation of handheld and other portable electronic applications. Photomasks have always been a necessary component in the Micro Manufacturing process.

There are three types of base material used to make photomasks: Soda Lime (SL), Quartz, and Polyester Film. Soda Lime is the most common material for photomasks, and typical glass mask sizes (SL and Quartz) can range from 3 inches square to 7 inches square, but even 14” square, 20” square and even larger are produced in our production facilities. The thickness of the plates ranges from 60 mils to 250 mils depending upon the size of the plate being imaged. Currently the most common sizes of masks used are 5 inches square 60 mils thick and 7 inches square 120 mils thick.

Film polyester photo-masks have less constraints on size, and can be made on sheets from 25cm x 30cm , upto a huge 2.4m long x 1.6m wide . The polyester base on the film is 0.18mm thick (7 mils). Due to the particle sizes in the emulsion used on a film mask, they have a lower resolution and connot compete with the quality of a chrome on glass photomask.