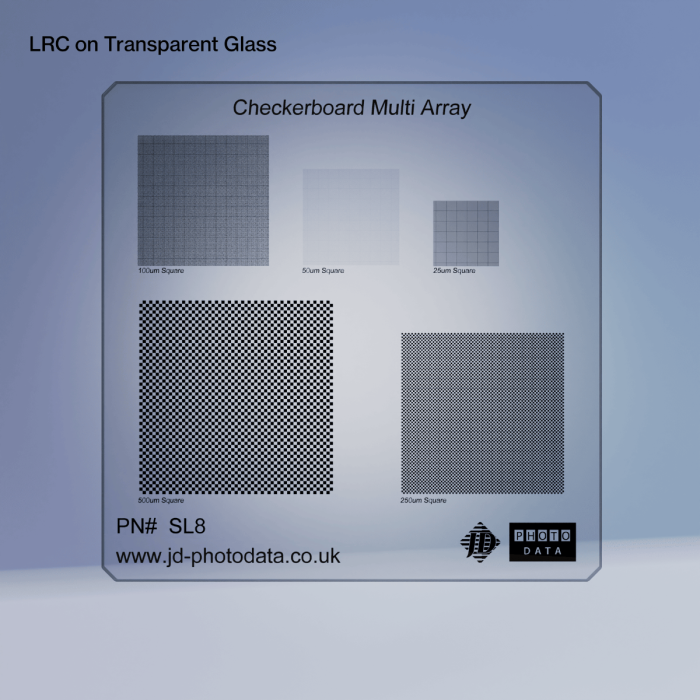

SL8 Checkerboard Multi Array Distortion Target

Determine the distortion of an imaging system.

High resolution chrome markings

Transparent glass or white glass

Checkerboard arrays are used to determine the MTF of camera lens, as well as sharpness and distortion of many different types of vision systems.

CONFIGURATION

- Material: Chrome on Transparent Soda Lime Glass, 1.5mm thick , available as 3" (75mm)

- Material: Chrome on White Glass, 1.25mm thick , available as 4" (100mm)

PATTERN DESCRITION

The pattern is a highly accruate checkerboard grid, drawn across the target using different size squares . The five grid arrays are 500um, 250 µm, 100 µm, 50 µm, and 25um

500Grid: 500um square, pattern area of 30 x 30mm

250Grid: 250um square, pattern area of 25 x 25mm

100Grid: 100um square, pattern area of 20 x 20mm

50Grid: 50um square, pattern area of 15 x 15mm

25Grid: 25um square, pattern area of 10 x 10mm

MATERIAL

Soda Lime Glass is the most common substrate used for targets, due to its good quality/price ratio. The glass is optically good, very flat and has no imperfections. It transmits a very wide variety of light sources from 350nm upwards, with an excellent UV transparency. Soda Lime glass has a thermal co-efficient expansion of 93 (10-7) which is approximately 10 ppm (parts per million) , and a transmittance value of 88% at 375-750nm, with a glass flatness class of 5um

White Diffuser Glass is a semi-opaque soda lime glass , which acts like a diffuser designed to create even illumination profiles. Unlike alternative materials, which create their diffusive properties through a coating or lamination process, the White Diffusing Glass is a solid diffuse material (30% transmission), allowing it to be used in any orientation. Because the surfaces are polished, the reflected light will be somewhat specular, while the transmitted light will be near-Lambertian. White Diffusing Glass is ideal for creating even illumination as an attenuator or as a viewing screen. The material has been double sided polished, with a glass flatness class of 2um.

Anti Glare spray coatings can be applied to the surface to reduce reflectivity when used with reflected light.

TURNAROUND

Our standard production turnaround is 3 days from receipt of order. We can offer faster services if required for more urgent orders.

INSPECTION

STANDARD: We inspect the piece by eye for flaws, design inaccuracies and contaminations. We measure the design to check that it conforms to the specifications, and record both of these measurements on our internal inspection records. Finally, we find the CD of the mask, measure that, record it, and also take a digital photo that is saved with the inspection log. We use Nikon MM40 at 900x magnification and an OGP ZIP 300 at 400 x magnifications for this.

CERTIFICATE OF CONFORMANCE: In addition to the standard inspection process described above, we will then document them via a Certificate of Conformance . Tolerances are per our standard tolerances.

CERTIFICATE OF MEASUREMENT: A combined conformance and measurement certificate. One square width and one pitch to be measured from each grid size. Tolerances are per our standard tolerances.

Please see the TECHNICAL sections, DOWNLOAD sections and FAQ for further information. If you still require clarification, please either email or click for LIVE SUPPORT.

MATERIAL SPECIFICATION

Soda Lime Glass is the most common substrate used for masks, due to its good quality/price ratio. The glass is optically good, very flat and has no imperfections. If used in a photo-lithographic process, glass can be used with a very wide variety of light sources from 350nm upwards, with an excellent UV transparency. Soda Lime glass has a thermal co-efficient expansion of 93 (10-7) which is approximately 10 ppm (parts per million) , and a transmittance value of 88% at 375-450nm, with a glass flatness class of 5um for the smaller plates and 10um for the larger plates. Some of the very big plates of 14" and above, may have a bigger flatness tolerance.

- Soda Lime Optical transmission of visible light = 88%

- Soda Lime Optical transmission of visible light = 375nm

- Soda Lime thermal expansion co-efficient = 10ppm

FREQUENTLY ASKED QUESTIONS

Q: The pattern doesnt represent what i need - can we alter it as a special design?

A: Yes ....The patterns here are standard products, but we can certainly transfer almost any design to the slide (Note the price will change accordingly)

Q: How long from order to dispatch?

A: Typically we have these products in stock on the shelf - however, it may take upto 5 days before they are dispatched. If you need the product more urgently, please contact us direct and we will do our best !

Q: Can you send me a scaled picture showing the detail in higher resolution?

A: Certainly, we have higher resolution graphics that we can email you. Please contact us via the Live Support or by Email.

Q: Can I have different materials?

A: Yes. Our standard products are Low Reflective Chrome on Soda Lie glass - but we can offer different base material (Quartz, Borofloat etc) and different masking materials (Aluminium, ITO, Gold etc), as well as simply different thicknesses of glass. There will be minimum order quantities for most of these special materials of at last 6 pieces, but with more "exotic" combinations considerably more.